Phone : +91-8700494563

Whatsapp : +91-9628485258

Non-Destructive Testing or NDT is a technique to inspect, test or analyze a material or a whole assembly for the discontinuities in its characteristics without damaging the system and its parts. The main advantage of NDT is that the sample can be used even after the testing is complete. It is a highly valuable technique because it saves time and money both.

This technique is more effective in comparison to other destructive test which is used to determine the physical properties of a material, whereas NDT determines the discontinuities in a material which further affect its characteristics.

Highly skilled, knowledgeable and experienced person is required to conduct these tests and SAFEMAXX QUALITY MANAGEMENT team of such talented individuals. Our NDT inspectors are well-trained in caring out Structural and Building Material testing, both on-site and in laboratory.

The regular services are being provided to several industries which include Thermal Power Plant, Gas Plant, Petroleum Plant, Automobile Plant e.t.c. We also offer Residual Life Assessment and Structural Safety Tests for bridges, buildings, water tanks huge structures and all.

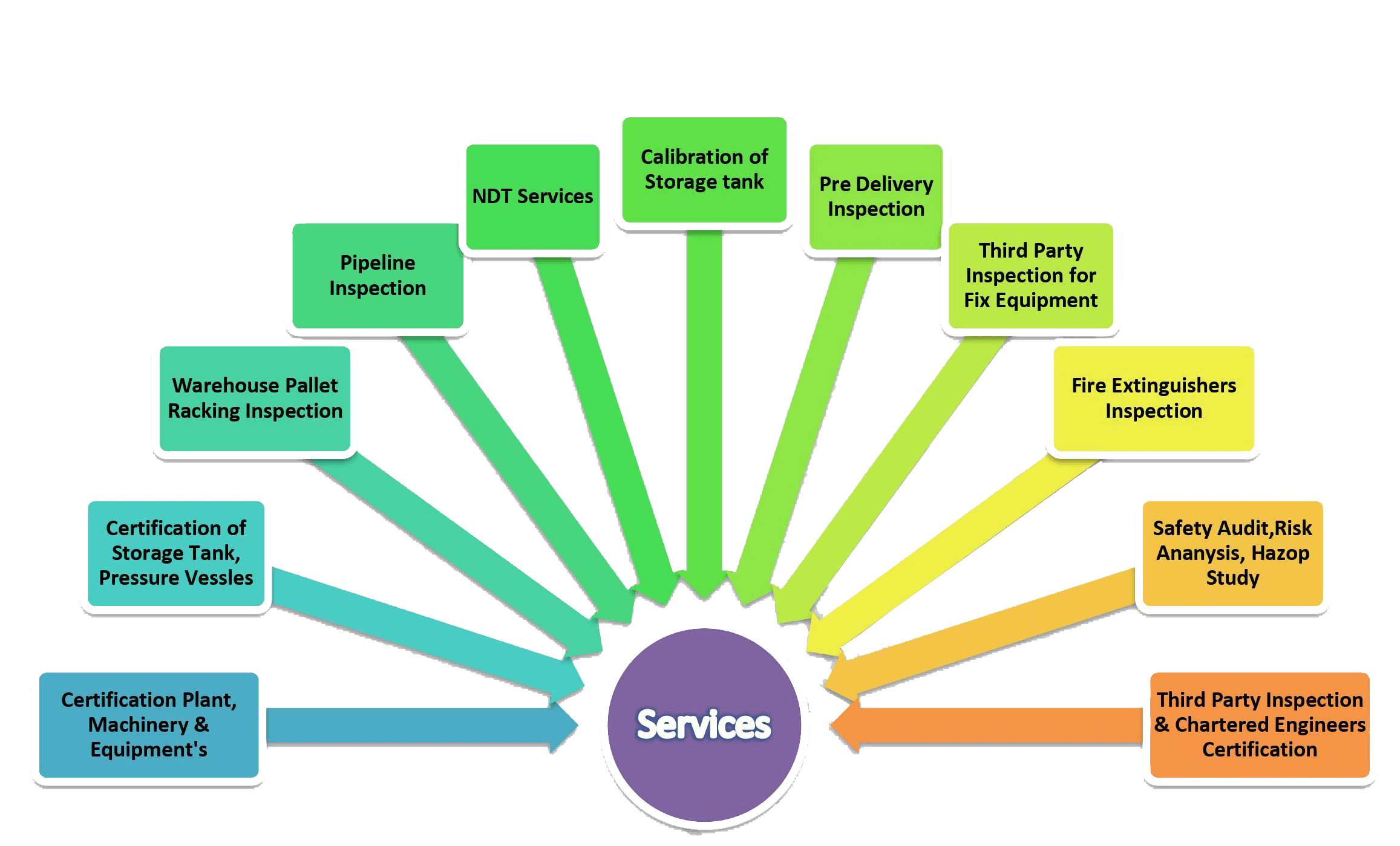

SAFEMAXX QUALITY MANAGEMENT Industrial Services is true global provider of Technical Inspection, Verification, Testing and Conformity Assessment for Industrial Markets. The core values of complete independence, transparency and integrity guide us in our mission to deliver first-class services on a constant high quality level to customers around the world. Our Teams of Engineers ensure that the quality and performance of products or installations meet applicable requirements, whether they are regulatory, voluntary or client specific. We help to improve the integrity, quality and efficiency of equipment, assure safe and health working conditions for employees and minimize the environmental impact of industrial activities.

SAFEMAXX QUALITY MANAGEMENT global experience in the Oil and Gas Industries include Process Plants and Refineries, Chemical Plants, Offshore Structure, Power Plant, Textile Plant, Automobile Plant and Storage and Distribution System as well as Oil and Gas Transmission Pipelines.

Pre-Delivery Inspection is a service we offer to our clients, whereby we carry out a series of tests and checks on the client's cargo/goods/vehicle before it can be presented to them. An extensive checklist (that is flexible depending on the goods being checked) is performed and filled to the latter before the customer is allowed to pick his/her cargo.

For instance, shipping a vehicle full of flammable liquids isn't the best of ideas so there is no gas and oil in the vehicle. Before a vehicle is ready for a customer to take delivery a Pre Delivery Inspection (PDI) must be performed on the vehicle.

This inspection not only ensures that the vehicle is in 100% perfect condition for the customer, but completes the finishing touches such as: filling the car up with gas, washer fluid, engine oil, installing the radio and license plate brackets, tightening bolts, check for damage, etc.

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.

The Third Party Inspection for Pressure Vessel article provides a sample procedure for Pressure Vessel Inspection and Testing manufacturing Shop.

Safemaxx Quality Management conducts audits on four continents and to all sectors of industry. The Indian Standard and Factory Act Specification details the critical requirements for an effective and efficient occupational health, safety and environmental management system. Implementing and maintaining the Indian Standard and Factory Act Standard, enables an organization to manage risks and improve both sustainability and business performance within the field of occupational health, safety and environmental management. The Indian Standard and Factory Act are based on the principles of:

The following Indian Standard and Factory Act Audit Guidelines provide a framework within which a company can develop, implement, evaluate, adapt and maintain an effective and efficient occupational health, safety and environmental management system.

The Piping Inspection article provides you with information about the inspection of piping and piping testing in a construction site, as well as in operating plants.

The construction code for process piping is ASME B31.3 Code and it covers the minimum requirements for design, materials, fabrication, inspection, testing, and commissioning.

With the above explanation, your inspection and test plan (ITP) for process piping needs to meet the requirements of ASME B31.3 Code.

ASME B31.3 refers you to the other ASME code sections for some activities. For example for welding refer to the ASME Code Section IX, pipe fitting design and selection to the ASME B16.5 and for Nondestructive testing to ASME Code Section V

The process piping design and construction is not under the ASME Code scheme of stamped items.

SAFEMAXX QUALITY MANAGEMENT Material Handling Equipment has the expertise to inspect your rack. We will

Perform a thorough inspection of your pallet racking to identify the following:

Pallet rack systems are an integral component of distribution centers and most manufacturing operations. Your employees are constantly working in and around your storage areas. Your racking is being used to store valuable material and products. As you strive to provide a safe work environment, it is important to inspect your pallet racks. An inspection allows you to assess if there are structural or safety deficiencies and if the material that is placed on the rack, is being properly supported.

What You Can Expect from a Pallet Rack Inspection

At SAFEMAXX QUALITY MANAGEMENT Material Handling, we can perform a pallet rack inspection to determine if your rack is structurally sound and safe for employees to load and work near. In addition to inspecting each component for damage, we will also examine the racking to ensure it is being used in a way that is consistent with generally accepted practices.

This is The Fire Triangle. Actually, it's a tetrahedron, because there are four elements that must be present for a fire to exist. There must be oxygen to sustain combustion, heat to raise the material to its ignition temperature, fuel to support the combustion and a chemical reaction between the other three elements. Remove any one of the four elements to extinguish the fire.

The concept of Fire Protection is based upon keeping these four elements separate.

Not all fires are the same. Per NFPA 10, burning may be classified into one or more of the following fire classes and your fire protection specialist will select the right fire extinguisher size and agent for the hazard.

Class A fires are fires in ordinary combustibles such as wood, paper, cloth, rubber, and many plastics.